CONTROL ELECTRONICS INC.

Monitoring Our Precious Resource

PDS-360 / 360DX Ultrasonic Open-Channel Flowmeter

Description

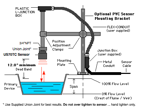

Control Electronics model PDS-360 Ultrasonic Open-Channel Flowmeter is a highly accurate, non-contacting liquid flow measuring system. The unit monitors flow through any standard primary flow device using sophisticated ultrasonic ECHO ranging techniques. The sensor is supported above the liquid flow providing accurate, instantaneous flow rates with totalized volume flow. The system has 2 independent 4-20 mA analog outputs, 4 control relays and 1 sampler pulse relay, all programmable.

A 200 day time stamped data logging provides 24 hour summary of flow rate, min / max flow, total flow for day and more.

Typical flow display with total and keypad

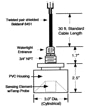

The US70TC Sensor uses an inexpensive twisted pair shielded cable, 700 feet maximum. The sensor uses a lower pulsed voltage than most other manufacturers. The sensor is easily mounted using PVC components and due to the low operating voltage, is considered non-hazardous, eliminating potential arcing of a faulty cable or connection.

The US70TC Sensor with built-in temperature probe, uses an inexpensive twisted pair shielded cable. No complicated multi-pair cable or expensive coaxial cable.

Variables Displayed On Backlit Digital LCD Display ( User Selectable )

1] GPM / Totalizer 2] MGD / Totalizer 3] Flow Depth inches / GPM 4] Flow Depth feet / GPM

5] Flow % / Temperature F°

Metric Equivalents

6] LPM / Total liters 7] Cm/h / Total Cubic Meters 8] Depth in cm / LPM 9] Depth mm / Cm/h;

APPLICATIONS

Monitoring Influent and Effluent flow in:

- Sewage Treatment Plants and Industrial Discharge

- Pre-Packaged Treatment Plants

- Municipal Sewers

- Residential Developments

- Irrigation Channels

- Agricultural Runoff

- Storm Sewer Runoff

FEATURES

Standard

- Quick, Easy, Menu Driven Programming

- Four Control Relays for Alarms, Pumps etc.

- One Pulse Relay for Sampler or Remote Counter

- 200 Day Data Logging of Daily Totals and Flow

Summary

- NEMA 4X, IP65 Rated Fiberglass Enclosure With

Clear Hinged cover

- Environmentally Safe PVC Sensor with built-in

temperature probe.

PRIMARY DEVICES

built-in Equations

- Parshall Flumes … 1” thru 144”

- Palmer Bowlus … 4” thru 72”

- Leopold Lagco … 4” thru 30”

- V-Notch Weirs … 22.5° to 120° degree

- Rectangular Weirs with or without end

contractions … 1.0” to 999.99”

- User Defined

Data Logging

The PDS-360 automatically logs daily flow for the past 200 days with auto wrap around. It will record the date, daily average GPM flow rate with the min / max rate, time stamped. Total flows for the day will also be logged. The logging sample rate is programmable from 0-99 minutes in 1 minute increments. All data may be viewed at the meter or downloaded using any standard communication package.

A time stamped EVENT list is also provided to record actions the flowmeter has made such as power lost, power ON, unit programmed, relays ON/OFF etc. All data is preformatted and can be downloaded to a PC.

For Programming Meter, RESETing Meter and Trouble Shooting go to SUPPORT.

Electronics

Power: 120/220 VAC, ±15%, 50/60 Hz @ 15 watts max.

Temperature: 20°F to 120°F

Display: 2 x 20 character, alphanumeric LCD with backlight

Totalizer: 8 digit accumulative with programmable multiplier;

x1, x10, x100, x1000

Outputs*: Two independent 4-20 mA isolated into 1000 ohm load

each, ±1.0% of full scale.

RS-232 terminal ( USB with adapter ), 4 alarm control

relays and 1 Sample Pulse relay, all programmable. Relay

contacts SPDT 5A/250 VAC

Span Range: 0-1.00” to 0-100.00” full scale - programmable

Dead Band: 12.0” to 36.0”

Resolution: 0.01”, 0.01 GPM ( LCD Display )

Accuracy**: ±0.5% of range. Calculated error ±0.04%

Memory: Flash and non-volatile RAM ( 3 V battery backup )

Equations: Parshall, Palmer Bowlus, Leopold Lagco flumes, V-notch

Weirs, Rectangular Weirs with or without end contractions,

User Defined.

Data Log*: 200 day, 24 hour flow summary: min, max, avg GPM, total

gallons - time stamped. ( down load or view on LCD

display )

Avg GPM flow rate with programmable log rate of 00-99

minutes ( 1 minute increments ) time stamped.

EVENT list time stamped ( view by down load only ) using

any standard communication software

* The PDS-360DX unit has no relay / RS-232 outputs or data logging

** Field conditions, such as turbulence, poor installation etc., may

affect the apparent accuracy.

PDS-360 / 360DX Open Channel Flowmeter Specifications 8/20

Sensor w/Temp Probe ( US70TC Sensor )

Material: PVC Housing, Epoxy

Beam / Freq.: 5° Conical, 40 Khz pulsed

Temperature: -10°F to 120°F operating

Cable: 30 foot twisted pair, Up to 700 ft. spliced in-field. Belden # 8451 or equal.

Dimensions: 3.0” dia. x 4.2” len

Mounting: 3/4” male ( 3/4” female with supplied union joint )

Rating: Sensor is considered explosion proof, corrosion resistant, immersible

Enclosure

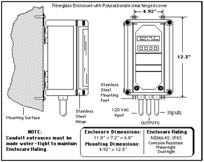

Material: Fiberglass with clear hinged Polycarbonate cover, stainless steel hinges

and mounting hardware

Rating: NEMA 4X, IP65, Dust-Tight, Water-Tight, Corrosion Resistant, CSA / UL

listed

Dimensions: 7.2” x 11.8” x 6.8”

Mounting: 4.92” x 12.3”

Options

PVC Sensor Mounting Kit; Additional Sensor cable; Additional Manuals; 120 VAC, 6 foot power cord installed

Warranty

The PDS-360 and 360DX units are pretested and inspected before shipping. Warranty is against defects in parts and workmanship for a period of one (1) year from ship date.

Specifications and Design are subject to change without notice.

These specifications supersede all other published specifications.

Made in USA

© Control Electronics Inc., 2020

Designing / Manufacturing Since 1980