CONTROL ELECTRONICS INC.

Monitoring Our Precious Resource

PSM-660 Pump Station Flow Monitor Controller

Description

The PSM-660 Pump Station Monitor offers the quickest, easiest and most accurate method to control and/or monitor flow through your sewage lift station. The system accepts a wide variety of input types including floats, contact closures, 4-20 mA level signal.

Use the PSM-660 to update and existing pump station, provide for a new installation, replace problematic Doppler or Mag meters or temporarily monitor a pump station for performance and liquid volume throughput. Simply enter the wet well dimensions ( round or rectangular ) and the pump(s) start/stop elevations with an optional intermediate elevation for inflow rate. The PSM-660 will do all the volume calculations and pump control (if desired) accurately, reliably, automatically.

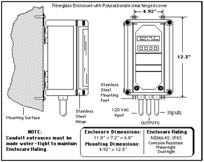

Proportional analog flow rate and level signals ( two 4-20 mA ) outputs are available for remote indicating, recording and process control. All circuits are protected in a NEMA 4X (IP65) fiberglass enclosure with a clear polycarbonate hinged cover.

APPLICATIONS

Monitoring Influent and Effluent flow in:

- Billing Purposes

- Flow Surveys

- Infiltration Studies

- Pump Evaluations

- Pump flow Monitoring

- Pump Control

- Replacing older flowmeters for improved accuracy

FEATURES

Standard

- Quick, Easy, Menu Driven Programming

- Five Control Relays for Pumps etc.

- Lead /Lag, Rotate or none of pumps

- 200 Day Data Logging

- NEMA 4X, IP65 Rated Fiberglass Enclosure With

Clear Hinged cover

- Multiple input types

- Pump Run Time Hour Meters

- Easy installation

Data Logging

The PSM-660 automatically logs daily pump and flow data with auto wrap around. It records the date, daily average GPM pump rate, total number of pump cycles, pumping run time for each pump and total pumped for each pump for the past 200 days.

A detailed logging of each pump cycle records the date, pump cycle number, start and run time of pump cycle, average inflow GPM rate, and GPM pump rate along with total pumped.

A time stamped EVENT list is included to record actions the monitor has made such as HI/LOW alarm, when unit was programmed, power loss, power ON etc.

Data may be downloaded to a PC using any standard communication package.

Data Logging

The PSM-660 automatically logs daily flow for the past 200 days with auto wrap around. A 24 HOUR SUMMARY logs number of pump cycles, run time for pumping, average GPM pump rate, the days pump total. Also the pump number and number of cycles, start and run time, inflow GPM rate and each pump run time (run hours). Total flows for the day and pump cycles will also be logged. All data may be viewed at the meter or downloaded using any standard communication package.

A time stamped EVENT list is also provided to record actions the meter has made such as power lost, power ON, unit programmed, alarms etc. All data is preformatted and can be downloaded to a PC.

Variables Displayed On Backlit Digital LCD Display ( User Selectable )

1] Filling Cycle / Total 2] Inflow GPM / Pumped GPM 3] Avg. GPM / Total 4] Start of Cycle / Run Time

5] Flow % / Days Total 6] Level Inches / Total (when using 4-20 mA input only

For Programming Meter or RESETing Meter go to SUPPORT.

Electronics

Power: 120/220 VAC, ±15%, 50/60 Hz @ 15 watts max.

Temperature: 20°F to 120°F

Display: 2 x 20 character, alphanumeric LCD with LED backlight

Totalizer: 8 digit accumulative with programmable multiplier;

x1, x10, x100, x1000

200 daily 8 digit totalizers

Outputs*: Two independent 4-20 mA isolated into 1000 ohm load

each, ±1.0% of full scale.

RS-232 terminal ( USB with adapter ), 5 pump/alarm

control relays, all programmable. Relay contacts SPDT 5A/

250 VAC

Inputs: Optically Coupled Floats, Contact Closures, 4-20 mA.

Clamp on current Sensors with contact closure (clamp on

user supplied)

Resolution: 0.01 GPM, 0.01 inches ( LCD Display )

Accuracy*: ±1.0 second run time, ±0.1% calculated error

Memory: Flash and non-volatile RAM ( 3 V battery backup )

Data Log: 200 day summary: Date, total pump cycles, total pump(s)

run time, total gallons pumped

Pump Cycle: Cycle number, start/run time, inflow rate

GPM, average pump rate GPM, total pumped for cycle

EVENT List: time stamped events ( view by down load

only ) using any standard communication software

* Note: field conditions, such as turbulence, poor installation etc., may

affect the apparent accuracy.

PSM-660 Pump Station Flow Monitor Specifications 8/20

Enclosure

Material: Fiberglass with clear hinged Polycarbonate cover, stainless steel hinges

and mounting hardware

Rating: NEMA 4X, IP65, Dust-Tight, Water-Tight, Corrosion Resistant, CSA / UL

listed

Dimensions: 7.2” x 11.8” x 6.8”

Mounting: 4.92” x 12.3”

Warranty

The PSM-660 units are pretested and inspected before shipping. Warranty is against defects in parts and workmanship for a period of one (1) year from ship date.

Specifications and Design are subject to change without notice.

These specifications supersede all other published specifications.

Made in USA

© Control Electronics Inc., 2020

Designing / Manufacturing Since 1980